For years, carbon accounting has been treated as a necessary evil, a compliance mandate that consumes time, drains resources, and delivers little business value. Companies pour effort into sustainability reporting only to walk away with a regulatory checkbox and nothing more.

But what if carbon accounting could actually drive profitability?

What if the same system that tracks your emissions could also help you cut energy waste, optimise operations, and even create new revenue streams?

That shift is happening now.

As organisations adopt IoT-driven carbon accounting, they are discovering that real-time emissions monitoring is far more than a compliance exercise; it is a strategic unlock for operational efficiency and bottom-line growth.

The Traditional Carbon Accounting Problem

For most companies, carbon accounting has long been a manual, painful, and backward-looking process.

Teams spend weeks gathering data from spreadsheets, utility bills, logbooks, and rough estimates. By the time the report is complete, the information is already outdated like driving a business while staring into the rear-view mirror.

Traditional processes rely on:

Manual data entry across multiple business units

Estimates based on emission factors or industry averages

Quarterly or annual reporting cycles

Limited visibility into real-time operations

High risk of human error, inconsistency, and data gaps

Yet the truth remains: You cannot manage what you do not measure. And you cannot optimise what you cannot see in real time.

Enter IoT: The Game Changer

IoT technology is fundamentally reshaping how companies capture, monitor, and act on their carbon data.

By deploying sensors and connected devices across operations, businesses can now collect emissions data automatically, continuously, and with unprecedented accuracy.

Think of IoT sensors as thousands of vigilant employees who:

never sleep,

never miss a reading,

and report instantly.

These devices track everything from machine-level energy consumption to fuel use, from HVAC performance to real-time environmental conditions inside industrial processes.

Real-Time Data Collection: From Guesswork to Precision

One of the largest breakthroughs IoT brings to carbon accounting is the elimination of estimations.

Instead of relying on averages, IoT delivers granular, real-time, activity-level data:

Smart meters track energy consumption down to individual machines.

Fuel sensors measure both volume and combustion efficiency.

Temperature and pressure sensors calculate emissions from industrial processes accurately.

The result is carbon data that is not just compliant but actionable. This transforms carbon accounting into an engine for operational intelligence.

The ROI Story: How IoT Turns Carbon Accounting Into a Profit Center

For decades, carbon accounting was seen as a compliance cost money spent with little return. IoT flips that narrative completely.

By providing real-time, accurate, granular insights into how energy and resources are actually being used, IoT reveals inefficiencies that directly impact profitability. Suddenly, carbon accounting isn’t just measuring impact, it's unlocking value.

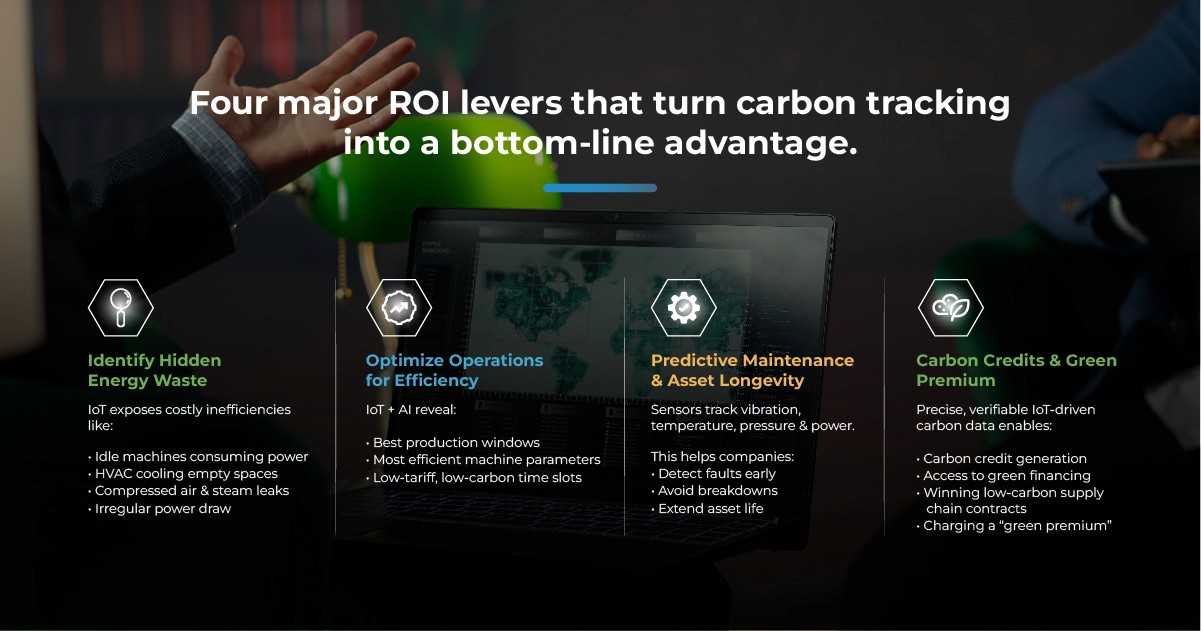

Below are four major ROI levers that turn carbon tracking into a bottom-line advantage.

Identify Hidden Energy Waste

The fastest and most immediate ROI comes from exposing waste that was previously invisible. IoT sensors reveal:

Machines running idle but still consuming power

HVAC systems overcooling/heating empty spaces

Compressed air leaks that cost lakhs annually

Pumps, motors, and utilities running inefficiently

Equipment drawing irregular or excess power

Once this waste becomes visible, companies can act quickly:

Shut down idle equipment

Fix leaks

Optimise HVAC schedules

Replace or repair inefficient assets

Result: Lower energy bills + lower emissions = achieved simultaneously. For many organisations, this alone recovers the entire IoT investment within months.

Optimise Operations for Efficiency

IoT doesn’t just detect waste it unlocks operational intelligence. Machine-level data combined with AI/ML can identify:

The best production windows when power is cheapest

The optimal machine speed that minimises energy per unit

Off-peak time slots with a cleaner energy mix

Inefficient sequences or batch processes

Conditions that increase fuel, steam, or electricity usage

In short, IoT reveals how to run operations at lowest carbon and lowest cost. This enables companies to:

Shift high-energy processes to low-tariff hours

Adjust production schedules based on grid-carbon intensity

Fine-tune machine parameters for peak efficiency

The outcome is better throughput with lower operational expense, a direct profitability boost.

Predictive Maintenance & Asset Longevity

A hidden but powerful ROI driver is predictive maintenance. IoT sensors constantly monitor:

Vibration

Temperature

Pressure

Power draw

Output consistency

These parameters signal early performance degradation. When a machine becomes inefficient, it consumes more energy and emits more carbon. With IoT insights, companies can:

Catch faults before failure

Prevent costly breakdowns

Schedule maintenance proactively

Extend asset life

Maintain optimal operating efficiency

Result: Higher uptime, reduced repair cost, and lower emissions, all contributing to higher profitability.

Carbon Credits & Green Premium

IoT-enabled carbon accounting creates financial opportunities, not just operational improvements. With precise, verifiable, real-time emissions data, companies can:

Generate and trade carbon credits

Qualify for low-carbon incentive programs

Access green financing at better rates

Win contracts from global customers demanding verified low-carbon supply chains

Charge a “green premium” for certified low-carbon products

In an increasingly sustainability-regulated world, accurate carbon data becomes a competitive advantage and a revenue driver.

Key Benefits That Drive Business Value

IoT carbon accounting delivers measurable business outcomes:

Automated Data Collection: Eliminates labor-heavy manual processes, reduces errors, and improves compliance efficiency.

Real-Time Alerts: Instant notifications when emissions spike, equipment fails, or processes drift enabling rapid correction.

Better Decision-Making: Accurate data empowers operations, procurement, and finance teams to make confident, ROI-backed decisions.

The Future Is Connected

This transformation is only beginning.

AI and machine learning are making carbon systems predictive, not just descriptive.

Edge computing is enabling faster, localised processing with minimal latency.

Connected supply chains will soon deliver real-time Scope 3 visibility.

Early adopters gain advantages that compound year after year:

lower costs

higher operational efficiency

stronger customer preference

superior compliance confidence

The leaders of tomorrow will be the companies that move from annual reporting to continuous intelligence.

Conclusion

Carbon accounting has evolved from a compliance burden into a strategic business lever and IoT is the catalyst behind this shift. By enabling real-time, accurate, granular emissions data, IoT helps companies:

eliminate waste,

optimize processes,

reduce operational costs,

and unlock new revenue opportunities.

This is no longer theory industries like automotive and manufacturing are proving the ROI every day. And as more companies adopt IoT-enabled carbon accounting, sustainability will not just align with profitability it will drive it.